Packaging for fresh vegetables is one of the most complex topics in the packaging solutions game, and for good reason. We don’t have to tell you that vegetables don’t come with built-in preservatives, so they’re much more likely to fall prey to degradation as they wait their turn on supermarket shelves.

The packaging has to do all of the heavy lifting, and by that same turn, the vegetable packaging process has to live up to the challenge. Getting the process right means fresh vegetables – either cut or untouched – have a longer shelf life and a fresher snap out of the bag.

But getting the process wrong? This can cost you money. As your NZ packaging experts, we’re taking a few minutes to unpack (literally) why the vegetable packaging process is so important and how your decisions can impact both freshness and shelf life.

Freshness, the Essential Factor

There’s no section of the grocery store where first impressions matter more. People expect freshness from their produce, and the way vegetables look in their packaging is secondary only to how they feel when customers pull them out. It’s about taste, texture, and nutritional value, all of which are signalled by the quality of the packaging solutions used to house them.

If you’re in the supermarket and supply game, you know that the longer produce remains crisp, colourful, and delicious, the more profitable it is. The key to extending that timeframe? Smart vegetable packaging processes, tailored to the needs of each vegetable type.

How the Packaging Process Impacts Your Vegetables

Each variety of vegetable needs something different from its grower, and the same is true for its packaging. The right vegetable packaging process has to account for a few vital factors that balance freshness, shelf life, and cost.

Moisture Control

Moisture is both a friend and foe to fresh produce. Too much moisture inside the packaging can lead to bacterial growth and premature spoilage. Too little, and the vegetables dry out and wilt. This delicate balance is crucial for products like leafy greens, which are particularly prone to wilting.

Oxygen Management

Vegetables continue to respire (breathe) even after they’ve been picked from the ground. This respiration uses up oxygen and releases carbon dioxide, so the last thing you want to do is suffocate your produce with your packaging solutions.

If the oxygen levels drop too low, the vegetables will begin to respire anaerobically, resulting in off-flavours, texture changes, and spoilage. Sealed packaging that still allows vegetables to respire can extend shelf life without damaging the vegetables due to other factors, such as moisture, which is a real lifesaver.

Temperature Control

While cold chain management is one of the most critical aspects of transporting vegetables from farm to supermarket shelf, packaging plays a significant role in this process. Temperature indicators and insulated solutions, when paired with proper cold chain management, help ensure a safe journey, allowing the product to stay fresher for longer.

Physical Damage Protection

Vegetables can be surprisingly delicate. Bumps, bruises, and cuts can accelerate spoilage by allowing bacteria and mould to take hold.

Well-designed vegetable packaging cushions the produce, minimising movement and impact damage during transport. This is particularly important for soft vegetables like tomatoes or courgettes, which also tend to show their damage much more easily.

Top Vegetable Packaging Methods to Pick From

Different vegetables require different types of packaging to ensure they stay fresh for as long as possible. Here are a few of the most common methods used today:

Perforated Bags

Perfect for vegetables like carrots, potatoes, and onions that need good airflow to stay fresh. Small perforations allow excess moisture and gases to escape, preventing internal condensation.

Clamshell Packaging

Popular for berries, herbs, and cherry tomatoes, clamshells offer both protection from bruising and a level of visibility that consumers appreciate. Properly ventilated clamshells also assist with air circulation, keeping contents fresher longer.

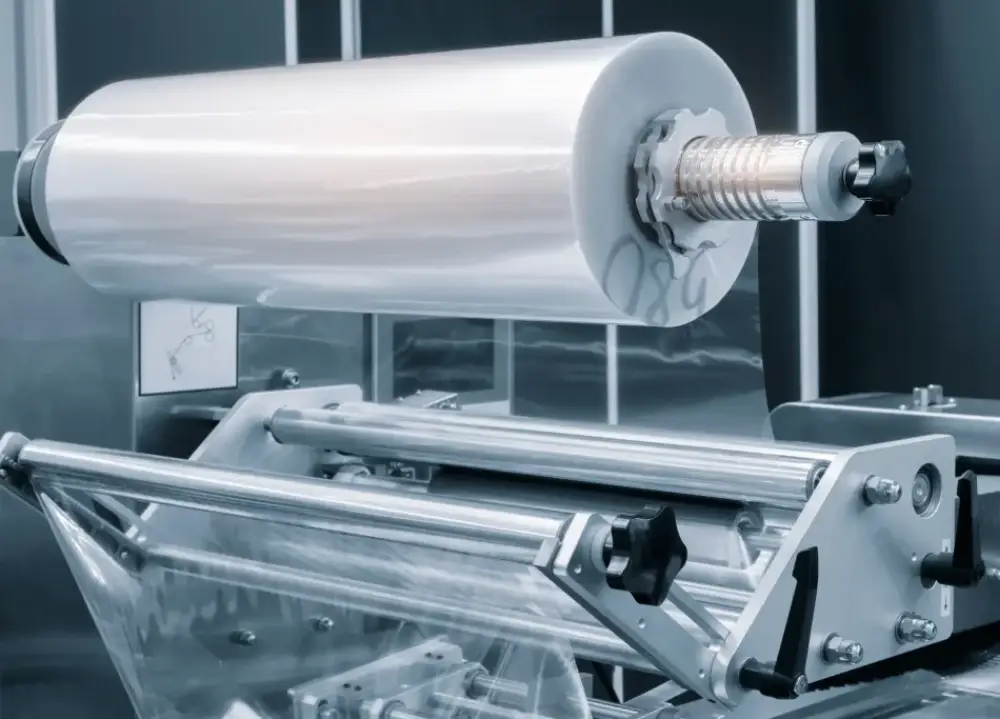

Shrink Wrap and Flow Wrap

Used particularly for leafy greens, cucumbers, and pre-cut salads, these wraps help to create a semi-sealed environment that preserves moisture levels without suffocating the produce.

Vacuum-Sealed Packs

Typically used for processed or pre-cut vegetables, vacuum sealing dramatically slows down oxidation and spoilage. However, it’s less suitable for very delicate vegetables that could get crushed by the pressure.

These methods are evolving even further under our guidance, as we incorporate technologies such as compostable or biodegradable films, active packaging to extend shelf life, and smart packaging that monitors conditions in real-time to provide feedback to retailers.

So, what is the full picture here? The vegetable packaging process goes beyond technical formalities. Your packaging is the guardian of your brand’s reputation, and a poorly executed process can turn stunning farm-fresh produce into an unappealing mess within days.

On the other hand, a well-designed packaging system can extend your product’s shelf life, reduce food waste, and enhance the overall experience across the entire supply chain. Grower, grocer, consumer; we all stand to benefit.

Give your vegetable products the longest possible shelf life with Allflex Packaging.

Our host of vegetable packaging solutions equips producers and suppliers just like you with the materials and techniques they need to preserve fresh vegetables for longer. Compete with the best brands in the market and build vital trust with your consumers with the help of our expert team of packaging consultants.

Get in touch today for an initial consultation to revitalise your vegetable packaging process!